Acorn Industrial Components

United Kingdom, Littlehampton

Acorn Industrial Components is a modern logistics company serving OEM manufacturing businesses who create high value, high technology equipment.

Main Services:

supply chain logistics, vendor managed inventory, c-part procurement, components supply, Third Party Logistics (3PL), kitting and assembly, MRO\/PPE industrial vending, aftermarket service logistics, warehouse consultancy, inventory analysis and planning

It has a long term 4IR and digital supply chain transformation plan to better provide these OEM clients with the best in supply chain services.

After learning his trade as an engineer in the UK Armed Forces, Acorn Industrial Components CEO Chris Till applied his expert logistics training to developing a supply chain logistics and components procurement company to serve OEM manufacturers in the UK and Europe.

— Acorn are trusted to supply clients who have a UK critical manufacturers designation.

— Acorn pride themselves on providing a bespoke service tailored to each company’s logistics needs.

— Acornis a family run firm, established in 1979 with ethical and sustainable business practice at heart.

Clients keep demanding greater value, visibility and logistical involvement. The Company’s services have evolved to cater to this by providng wrap-around supply chain consultancy and services such as 3PL, VMI, MRO/PPE vending, and assembly for smart manufacturers. These services live alongside foundational services of components and fasteners supply, procurement and delivery solutions.

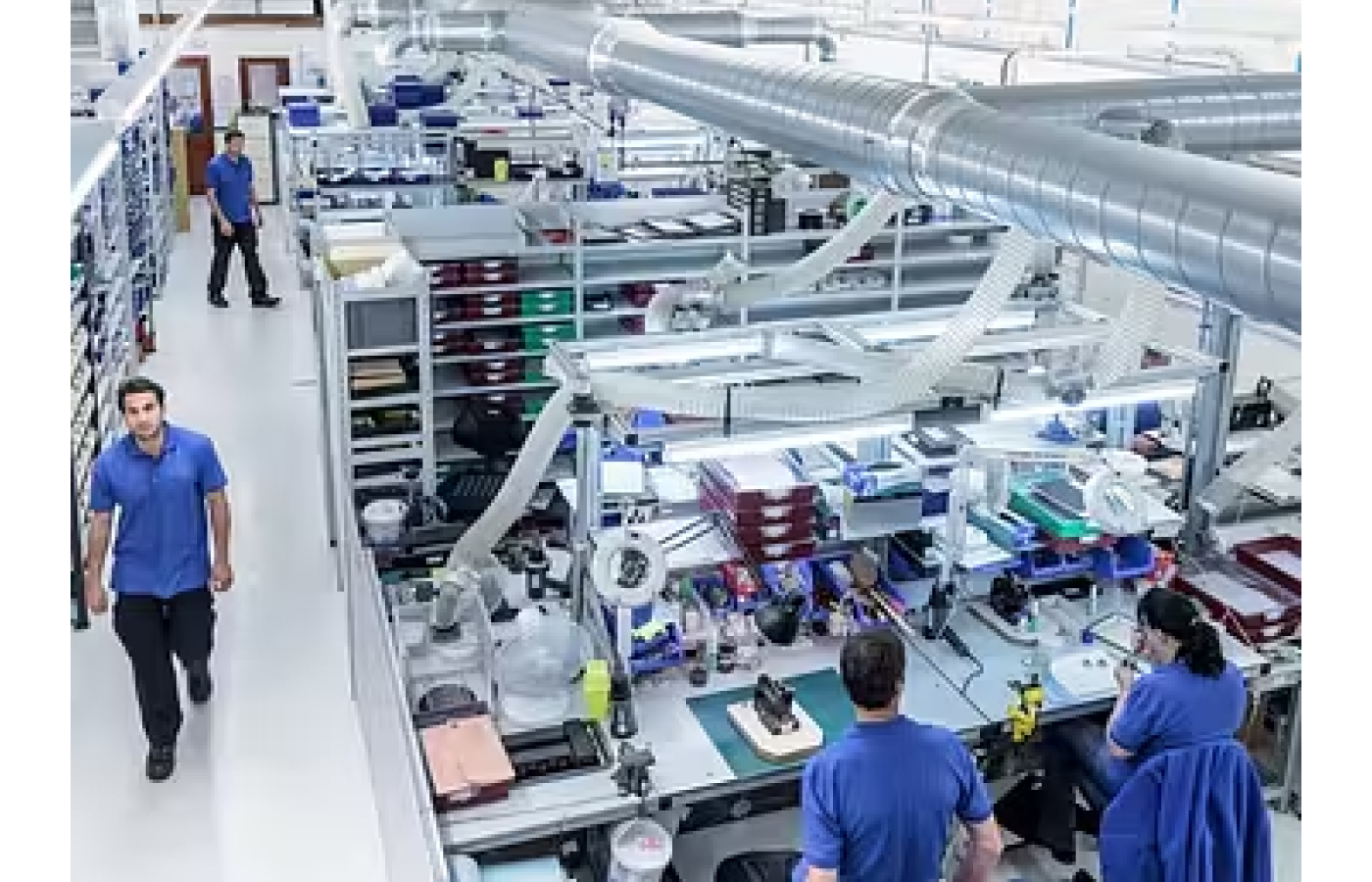

With burgeoning demand, the firm recently took the opportunity during the Pandemic to move from original facilities to centralise services and double service and warehousing space. With the new headquarters in Littlehampton, Acorn is a perfectly placed to cater to manufacturing in the South of England. At over double the size of the Company’s original Ditchling home, the West Sussex site at Littlehampton is a modern warehousing and logistics services facility with:

– integrated warehousing technologies for increased tracking & stock visibility.

– modern racking & pallet management with more efficient picking, packing & time-to-transport.

– heightened workplace safety management & COVID measures.

– full ESD control & clean room, along with specialised kitting & assembly areas.

– 10,000 sq ft of upgraded storage (room for 400 pallets).

Acorn are emerging from the recent chaotic business environment having embraced the challenge of the global pandemic, and turning adversity into opportunity. How? By updating and overhauling business practices and services to continue improving and providing the highest quality service to manufacturing companies as a trusted supply chain partner.